Profinet Gsdml Files

Download: ATV71 PROFINET gsdml file - Altivar 71 Plus,Altivar 71,Altivar 71 Plus-LH,Altivar 71Q. Number of backplane slots minus one for PNS and at least one for a power supply. IO data per station 2880 bytes total 1440 bytes of input data 1440 bytes of output data. Configuration V2.3 GSDML file is included with Proficy Machine Edition; available for import into 3rd-Party tools.

Profinet (usually styled as PROFINET, as a portmanteau for Process Field Net) is an industry technical standard for data communication over Industrial Ethernet, designed for collecting data from, and controlling equipment in industrial systems, with a particular strength in delivering data under tight time constraints (on the order of 1ms or less).[1] The standard is maintained and supported by PROFIBUS & PROFINET International (PI) , an umbrella organization headquartered in Karlsruhe, Germany.

- 1Functionalitys

- 2Technology

- 2.3IO connection life-cycle

- 2.7Isochronous communication

- 3Profiles

Functionalitys[edit]

Peripherals[edit]

Interfacing to peripherals is implemented by PROFINET IO.[2][3] It defines the communication with field connected peripheral devices. Its basis is a cascading real-time concept. PROFINET IO defines the entire data exchange between controllers (called 'IO-Controllers') and the devices (called 'IO-Devices'), as well as parameter setting and diagnosis. IO-Controllers are typically a PLC, DCS, or IPC; whereas IO-Devices can be varied: I/O blocks, drives, sensors, or actuators. PROFINET is designed for the fast data exchange between Ethernet-based field devices and follows the provider-consumer model.[2] Field devices in a subordinate PROFIBUS line can be integrated in the PROFINET system seamlessly via an IO-Proxy (representative of a subordinate bus system). A device developer can implement PROFINET with any commercially available Ethernet controller.[2] It is well-suited for the data exchange with bus cycle times of a few ms. The configuration of an IO-System is similar to PROFIBUS.

Conformance Classes (CC)[edit]

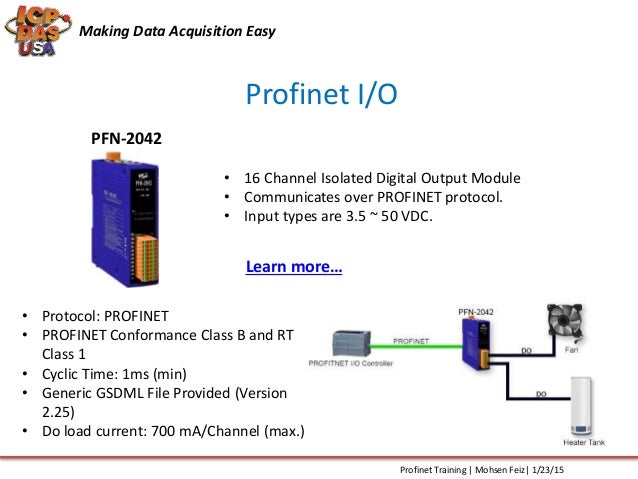

Applications with PROFINET can be divided according to the international standard IEC 61784-2 into three conformance classes:

- In Conformance Class A (CC-A), only the devices are certified. A manufacturer certificate is sufficient for the network infrastructure. This is why structured cabling or a wireless local area network for mobile subscribers can also be used. Typical applications can be found in infrastructure (e.g. motorway or railway tunnels) or in building automation.

- Conformance Class B (CC-B) stipulates that the network infrastructure also includes certified products and is structured according to the guidelines of PROFINET IO. Shielded cables increase robustness and switches with management functions facilitate network diagnostics and allow the network topology to be captured as desired for controlling a production line or machine. Process automation requires increased availability, which can be achieved through media and system redundancy. For a device to adhere to Conformance Class B, it must communicate successfully via PROFINET RT, have two ports (integrated switch), and support SNMP.

- With Conformance Class C (CC-C), positioning systems can be implemented with additional bandwidth reservation and application synchronization. Conformance Class C devices additionally communicate via PROFINET IRT.

- As of PROFINET V2.4 (June 2019), Conformance Class D (CC-D) was introduced which corresponds to CC-B and CC-C, except with communication via Time Sensitive Networking Ethernet being specified.

Technology[edit]

Three protocol levels are defined:

- TCP/IP for non time-critical data and the commissioning of a plant[2] with reaction times in the range of 100 ms

- RT (Real-Time) protocol for PROFINET applications[2] with up to 10 ms cycle times

- IRT (Isochronous Real-Time) for PROFINET applications in drive systems[2] with cycles times of less than 1 ms

The protocols can be recorded and displayed using an Ethernet analysis tool such as PROFINET Commander[4], PRONETA[5] or Wireshark.

Relations[edit]

A PROFINET system consists of the following devices:

- The IO-Controller, which controls the automation task.

- The IO-Device, which is a field device, monitored and controlled by an IO-Controller. An IO-Device may consist of several modules and sub-modules.

- The IO-Supervisor is software typically based on a PC for setting parameters and diagnosing individual IO-Devices.[3]

An Application Relation (AR) is established between an IO-Controller and an IO-Device. These ARs are used to define Communication Relations (CR) with different characteristics for the transfer of parameters, cyclic exchange of data and handling of alarms.[2]

Station Description[edit]

The characteristics of an IO-Device are described by the device manufacturer in a General Station Description (GSD) file. The language used for this purpose is the GSDML (GSD Markup Language) - an XML based language. The GSD file provides the supervision software with a basis for planning the configuration of a PROFINET system.[2][3]

IO connection life-cycle[edit]

The PROFINET connection life-cycle describes the connection between a PROFINET IO-Controller and IO-Device. The connection allows the cyclic exchange of process I/O data, and the acyclic handling of alarms. The PROFINET connection life-cycle consists of address resolution, connection establishment, parameterization, process IO data exchange / alarm handling, and termination.[2]

Address resolution[edit]

A PROFINET device is identified on the PROFINET network by its station name.[note 1] Connection establishment, parameterization and alarm handling are implemented with User Datagram Protocol (UDP), which requires that the device also be assigned an IP address. After identifying the device by its station name, the IO-Controller assigns the pre-configured IP address to the device.[2]

Connection establishment[edit]

Connection establishment starts with the IO-Controller sending a connect request to the IO-Device. The connect request establishes an Application Relationship (AR) containing a number of Communication Relationships (CRs) between the IO-Controller and IO-Device.[3] The connect request defines some CRs within the AR. The following CRs are supported:

- I/O data CRs support the point-to-point exchange of cyclic input and output process data between the IO-Controller and IO-Device.

- A record data CR supports the exchange of log data.

- An alarm CR supports the handling of alarms.

- A multicast CR allows cyclic process data to be published by one node for consumption by any number of consumers.[2]

In addition to the AR and CRs, the connect request specifies the modular configuration of the IO-Device, the layout of the process IO data frames, the cyclic rate of IO data exchange and the watchdog factor.

Acknowledgement of the connect request by the IO-Device allows parameterization to follow. From this point forward, both the IO-Device and IO-Controller start exchanging cyclic process I/O data frames. The process I/O data frames don't contain valid data at this point, but they start serving as keep-alive to keep the watchdog from expiring.

Parameterization[edit]

The IO-Controller writes parameterization data to each IO-Device sub-module in accordance with the General Station Description Mark-up Language (GSDML) file. Once all sub-modules have been configured, the IO-Controller signals that parameterization has ended. The IO-Device responds by signaling application readiness, which allows process IO data exchange and alarm handling to ensue.[2][3]

Process IO data exchange / alarm handling[edit]

Profinet Gsdml Files 2017

The IO-Device followed by the IO-Controller start to cyclically refresh valid process I/O data. The IO-Controller processes the inputs and controls the outputs of the IO-Device.[3]Alarm notifications are exchanged acyclically between the IO-Controller and IO-Device as events and faults occur during this phase in the PROFINET connection life-cycle.[2]

Termination[edit]

The connection between the IO-Device and IO-Controller terminates when the watchdog expires.[3] Watchdog expiry is the result of a failure to refresh cyclic process I/O data by the IO-Controller or the IO-Device.[2] Unless the connection was intentionally terminated at the IO-Controller, the IO-Controller will try to restart the PROFINET connection life-cycle.

IO addressing[edit]

Every module within a PROFINET network has three addresses:

- Device name, a logical name for the module within the total configuration

TCP/IP[edit]

Because PROFINET optionally uses TCP/IP, a MAC and IP address are used. A MAC address changes if the device is replaced. An IP address is a form of network addressing which may be dynamically assigned. Because there was a need for a fixed address a device name is used.

For allocation of the IP address, subnet mask, and default gateway two methods are defined:

Real Time[edit]

Within PROFINET, process data and alarms are always transmitted in real time (RT). Real time in PROFINET is based on the definitions of IEEE and IEC, which allow for only a limited time for execution of real-time services within a bus cycle. RT communication represents the basis for the data exchange in a PROFINET system. Real-time data are treated with a higher priority than TCP(UDP)/IP data. This type of data exchange allows bus cycle times in the range of less than 10 ms.

PROFINET IO data communicated over PROFINET RT uses EtherType 0x8892.

Isochronous communication[edit]

Isochronous data exchange with PROFINET is defined in the Isochronous Real-Time (IRT) concept. The data exchange cycles are usually in the range of a few hundred microseconds up to a few milliseconds. The difference to real-time communication is essentially the high degree of determinism, so that the start of a network cycle is maintained with high precision. The start of a network cycle can deviate up to 1 µs (jitter). IRT is required, for example, for motion control applications (positioning control processes) because these devices need to be synchronized. Coexistence with PROFINET RT and TCP/IP frames on the same cabling is still maintained.

Synchronization[edit]

PROFINET IRT uses the transparent clock mechanism to synchronize PROFINET IRT devices. The transparent clock mechanism is specified in IEEE 1588-2008 (1588 V2). This creates one control loop between the master clock and slave clocks.

Bandwidth Reservation[edit]

The bandwidth reservation method reserves time (bandwidth) on the network for PROFINET frames sent via IRT. A separate time domain is created at the beginning of a network cycle, during which all IRT frames are sent. After the IRT time domain is completed, PROFINET RT and finally non-time-critical TCP/IP frames are sent.

Scheduling[edit]

Because the controller knows the topology of the network via LLDP, it sends IRT frames based on this topology. IRT frames destined for IRT devices furthest from the controller are sent first in the IRT time domain.

Profiles[edit]

Profinet Gsd File Editor

Profiles are pre-defined configurations of the functions and features available from PROFINET for use in specific devices or applications. They are specified by PI working groups and published by PI. Profiles are important for openness, interoperability and interchangeability, so that the end-user can be sure that similar equipments from different vendors perform in a standardized way.

There are PROFINET profiles for encoders, robots, and process instruments, for example. Other profiles have been specified for motion control (PROFIdrive) and Functional Safety (PROFIsafe).

Another profile is PROFIenergy which includes services for real time monitoring of energy demand. This was requested in 2009 by the AIDA group of German automotive Manufacturers (Audi, BMW, Mercedes-Benz, Porsche and Volkswagen ) who wished to have a standardised way of actively managing energy usage in their plants. High energy devices and sub-systems such as robots, lasers and even paint lines are the target for this profile, which will help reduce a plant's energy costs by intelligently switching the devices into 'sleep' modes to take account of production breaks, both foreseen (e.g. weekends and shut-downs) and unforeseen (e.g. breakdowns).

PROFIsafe[edit]

PROFIsafe (PROFIBUS safety or PROFINET safety) is a safety communication technology for distributed automation. Its specification for PROFIBUS DP and PROFIBUS PA was published first in 1999. Extensions for the Ethernet based PROFINET IO followed in 2005.

The IEC 61508 standard specified how microcontrollers and software can be used in safety automation. This triggered the development of PROFIsafe, which was to integrate safety into the existing standard PROFIBUS fieldbus technologies. PROFIsafe is designed as a separate layer on top of the fieldbus application layer to reduce the probability of data transmission errors. PROFIsafe messages use standard fieldbus cables and messages. PROFIsafe does not depend on error detection mechanisms of underlying transmission channels, and thus supports securing of whole communication paths, including backplanes inside controllers or remote I/O. PROFIsafe coined the term 'Black Channel' for this concept, which was adopted by other safety fieldbusses. PROFIsafe can be used in safety applications up to Safety Integrity Level 3 (SIL) according to IEC 61508, Performance Level 'e' (PL) according to ISO 13849, or Category 4 according to EN 954-1.

PROFIsafe uses error and failure detection mechanisms such as:

- Consecutive numbering

- Timeout monitoring

- Source/destination authentication

- Cyclic redundancy checking (CRC)

PROFIsafe was standardized in IEC 61784-3-3 and Chinese standard (GB/Z 20830-2007).

Organization[edit]

PROFINET is defined by PROFIBUS and PROFINET International (PI) and backed by the INTERBUS Club and, since 2004, is part of the IEC 61158 and IEC 61784 standards.

See also[edit]

Notes[edit]

- ^The station name is a user-configurable alpha-numeric description of up to 240 characters

References[edit]

- ^'Easy PROFINET implementation'(PDF). Archived from the original(PDF) on 2015-04-02. Retrieved 2015-03-10.Cite uses deprecated parameter

deadurl=(help) - ^ abcdefghijklmn'PROFINET System Description'. PROFIBUS Nutzerorganisation e.V. October 2014. Order Number 4.132.

- ^ abcdefgManfred Popp. Industrial communication with PROFINET. PROFIBUS Nutzerorganisation e.V. (PNO). Order no.: 4.182.

- ^'PROFINET Commander – Take Command of your PROFINET Network'. profinetcommander.com. Retrieved 2019-08-01.

- ^'PRONETA - PROFINET Portfolio - Siemens Global Website'. Retrieved 2018-11-19.

Further reading[edit]

- Raimond Pigan, Mark Metter: Automating with PROFINET, 2nd rev. and enl. edition. 2008, ISBN978-3-89578-294-7